Surface Engineering for parts made by Additive Manufacturing (Step 1)

Programme

GSTP

Programme Reference

G61C-007QT

Prime Contractor

CRM CENTRE DE RECHERCHES METALLURGIQUES ASBL

Start Date

End Date

Status

Closed

Country

Belgium

Objectives

The objective is to evaluate the surface finishing technique for AM parts in order to derive guidelines for future applications.

Description

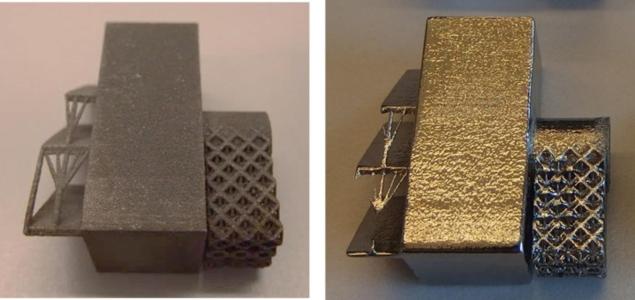

Within this activity, the surface finish techniques that can be applied to AM build hardware will evaluated. The surface coating techniques will be evaluated, including electro and electroless depositions, surface conversion, anodising and paint for few widely used space materials (e.g. Ti6Al4V, AA316L, A357.0). The surface finishing techniques will also be evaluated including chemical milling, shot pinning, honing and electrochemical polishing. The combination of the two methods will also be investigated. Guideline on surface treatments for AM made parts will be established.

Firstly the main surface finish used in space will be applied on flat samples of materials made using AM and the impact of the AM process on surface properties will be measured. In a second step, more complex geometries and requirements, derived from space hardware that could be manufactured in the future using AM technologies, will be made to establish the limitations in applying the selected surface treatments. Alternative finishing techniques will be evaluated and guidelines will be proposed.

Application Domain

Generic Technologies

Technology Domain

24 - Materials and Manufacturing Processes

Competence Domain

2-Structures, Mechanisms, Materials, Thermal

Keywords

32-Clean Space

Initial TRL

TRL 2

Target TRL

TRL 4

Achieved TRL

TRL 4