Citric Acid as a Green Replacement for Steels Passivation

The objective of the proposed study is to evaluate the suitability of the environmental friendly citric acid process for replacing the health hazardous nitric acid in passivating stainless steels used for manufacturing spacecraft and ground support structures on applications requiring corrosion resistance. The selected process applied to widely used alloys shall demonstrate with significant test evidence to meet the performance and reliability requirements necessary for ESA missions.

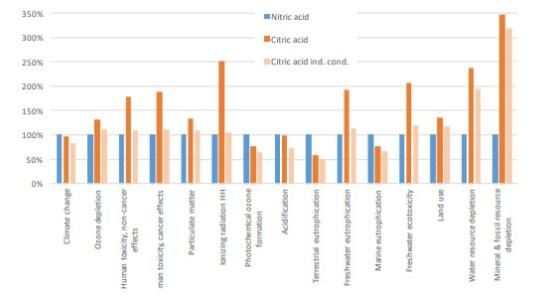

Stainless steels are major manufacturing materials used in spacecraft and ground support structures on applications requiring corrosion resistance including storage and handling of liquids and waste, propulsions systems, components within thermal protection systems and fasteners such as high-reliability and high strength bolts. Passivation of stainless steel has two purposes: 1) it is necessary to remove ?free iron? contamination left on the surface from machining and fabrication that can result in corrosion damage and 2) it forms an oxide film that protects the stainless steel from corrosion.Nitric acid is currently the most widely used passivating solution widely adopted in industrial applications. However, nitric acid has multiple environmental, safety, and process disadvantages. Nitrogen oxides (NOx) are considered greenhouse gases and are volatile organic compounds (VOCs) that contribute to smog. NOx increase nitrogen concentration (leading to oxygen depletion) in bodies of water and poses worker safety issues. Nitric acid can remove beneficial heavy metals (nickel, chromium, etc.) from surface of the substrate and requires significant handling and disposal costs of hazardous materials.Citric acid passivation has been recently proposed as a green replacement for stainless steels passivation processes in different industrial sectors, including fasteners, medical devices, semi-conductors, automotive and aerospace. Citric acid passivation offers many advantages w. r. t. environmental impacts: it is biodegradable, it is not considered a hazardous waste, it does not create toxic fumes during the passivation process and it does not remove beneficial heavy metals from the surface. Citric acid provides passivation of stainless steel while providing worker and environmental safety, versatility, ease of use, less maintenance and lower costs.The study proposed here refers to an activity of common interest between ESA and NASA in the effort of developing environmental friendlier materials, processes and coating systems able to provide the same performances. The synergy between the two Agencies is key to optimise costs of the whole test campaign guaranteeing sharing of activities and test results and avoiding duplication of efforts.The present activity, covering the ESA contribution, is split into two phases:Phase 1:? The objective of the first phase is to screen spacecraft as well as launchers systems in order to identify commonly used stainless steel alloys as well as applications where large materials quantities are required.? Perform for the selected materials candidates Life Cycle Assessment (LCA) in order to assess the health and safety related impacts of the nitric acid passivation processes currently applied.? Select a citric acid passivation process and the relevant applicable standard to be applied to the selected materials candidate and perform a Life Cycle Assessment for the selected process.Phase 2:? Submit the selected material candidates passivated using both nitric as well as citric acid routes to a series of laboratory testing including:? Compare all results with the two materials systems as well as the performed LCA?s.