Germanium (Ge) has been identified as one of the major environmental hotspots of ESA’s space missions. As one of the critical raw materials the use of it (mainly driven by solar cells) is a major contributor to mineral resource depletion.

Today, Germanium is used as a growth template for certain solar cells. While the thickness of the Germanium on a solar cell level is extremely thin, around 140μm, actually only 10-20μm are actively being used. The rest is structural.

An activity with TDE and Umicore, Belgium, has developed and implemented a recycling process for Germanium with specific steps for areas where recycling is not currently done, such as the thinning process of the germanium wafers used for the cells.

The activity has also developed a process for manufacturing highly efficient solar cells using alternative growth templates that allow for a significant reduction of Germanium used per cell.

In collaboration with Azur Space, a recycling path has been implemented that allows for 80% of the germanium to be recovered from the backgrinding process to thin the germanium used in a solar cell.

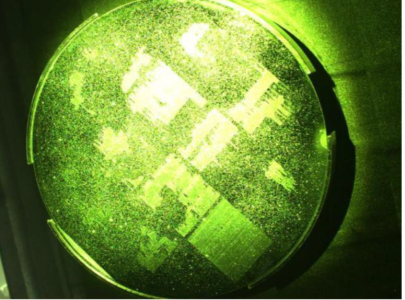

In addition, the first growth trials of germanium engineered substrates have been successfully performed with very promising resultsLife cycle analysis studies demonstrated that implementating the proposed recycling process reduced the germanium consumption by 25% in total, but more could still be achieved.

While the impact this would have on a spacecraft’s environmental footprint is clear, the implementation of the recycling process also has economic benefits.

Today, Ge is used as a growth template for III-V based solar cells and also serves as the lowest active junction. While the thickness of the Ge on solar cell level is around 140?m, actually only 10-20?m are really active. Therefore, in order to become thinner and lighter, solar cell manufacturers start to thin down the Ge wafers after cell processing by grinding, etching or lift-off processes (to reduce weight). However, this Ge waste is today not recovered since no economical process exists. Therefore, one idea to improve the use of Germanium is to effectively recover the Ge and assure a cost effective recycling stream. Another possibility to become lighter and reduce the amount of Ge is to start from a different growth template such as e.g. Silicon (Si) that is one of the most abundant materials on earth. Furthermore, it is s also cheaper and lightweight. However, Si wafers are not compatible for growing III-V solar cells directly on them. Therefore, a dedicated development is needed for that option or equivalent alternatives.

In previous LCA studies, Germanium (Ge) has been identified as one of the major environmental hotspots of ESA?s space missions. Ge is one of the Critical Raw Materials and the use of it (mainly driven by the solar cells) is the major contributor for the impact of the spacecraft in mineral resource depletion. Even though recycling processes exist to a certain extent (as a minimum within the Ge wafer manufacturer UMICORE) other Ge waste, e.g. Produced during the grinding process when solar cells are thinned, is today not fully recovered.

This activity is an important step to mitigate the environmental impact of ESA space missions.

This activity encompasses the following tasks:

1. Recycling

a. Evaluate recycling concepts with regard to feasibility, ecology and economy

b. Identify the best concept and carry out practical tests

c. Specify a recycling unit and implement the system into the production line

2. Investigate options to improve use of Ge such as Virtual substrate (e.g. Ge on Si substrate).

a. Develop buffer layer to grade the virtual substrate, e.g. From Si to Ge

b. Develop Ge growth on virtual substrate

c. Growth of III-V solar cell structures on virtual substrates.

d. Engineering tests on solar cell structures

A Life Cycle Assessment of the two options (Recycling and Virtual substrate) need to be performed. A comparison of these alternatives with current technology and manufacturing processes is required.