Developing Cold Spray as the next generation Additive Manufacturing technology

Demonstrate the feasibility of additive layer manufacturing through cold spray technology

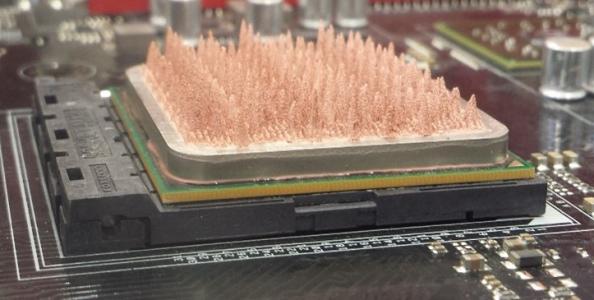

Cold Spray (CS) is a revolutionary technology which can allow for the manufacturing of coatings onto engineering components in a simple and environmentally friendly manner. With the right level of automation and robotic stage design, there is the possibility that this novel technique could also produce 3D additively-manufactured components with low fly-to- buy ratios. Several material combinations can be envisaged including, for instance the deposition of Inconel625, a Nickel alloy that is otherwise difficult to process with additive layer manufacturing.The project is segmented into two phases. In the short term (0-18 months) a low-cost solution to replace the use of high-powered lasers to pre-treat surfaces and/or the replacement of helium as the fluid carrier will be realized; thus making CS accessible to a considerably larger market. The second phase (18-48 months) will focus on the development of innovative solutions to improve deposition efficiency and process capabilities.The study will utilize the Cold Spray facility already exists within Trinity College Dublin premises.