Efficient mounting of MLI blankets to spacecraft structures

Programme

GSTP

Programme Reference

GT17-017MT

Prime Contractor

RUAG SPACE GMBH

Subcontractors

Start Date

End Date

Status

Closed

Country

Austria

Objectives

The objective of this activity is to develop a faster and reliable method for installing MLI blankets when compared to the current state-of-the-art methods, to shorten integration time and reduce impact on system AIT, while maintaining MLI integrity and installation constraints. The alternative solutions are expected to offer advantages over the current methods in terms of mass, flexibility, ease of installation and removal, time required for installation and finally the related cost. A breadboard shall be developed and tested for critical function verification in a relevant environment.

Description

Satellites have an outer skin of multilayer insulation blankets layer that is needed to control the thermal balance of the spacecraft (S/C).

These blankets need to be fixed to the S/C structure to withstand launch loads and provide the required thermal performance taking into account field-of-views of instruments and other payloads as well as access constraints.

MLI blankets are currently mounted to the S/C structure by a cut-to-fit approach of the either MLI lay-ups or at least MLI templates involving bonding of more than 1000 -1500 pcs. of MLI attachments (stand-offs and / or velcros) for a typical satellite. This is a very time consuming task, which takes several weeks to be completed. Furthermore the more disturbances, the more thermal impact on the overall MLI performance is to be expected.

An advanced MLI mounting concept shall be investigated, which minimises the number of attachments needed for a reliable fixation of the MLI blankets taking into account mechanical aspects as exposed to during launch. Focus is on how to ensure that the mechanical and pressure loads can be taken by a reduced number of attachments without impacting the MLI integrity, the field-of-view requirements as well as other precise positioning requirements on the satellite. Contamination and cleanliness aspects need to be addressed. A number of initiatives to develop this new mounting approach have already been carried out by MLI suppliers. Grounding aspects have also been covered. It is now envisaged to develop further the TRL/maturity on the basis of ESA needs on most projects (strong benefits in reducing system AIT time and cost).

The main tasks foreseen in the frame of this activity are the following:

- Characterisation and consolidation of state-of-the-art methods and identification / selection of alternative concepts

- Detailed design of these concepts

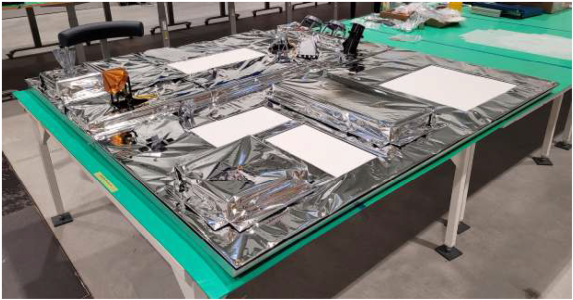

- Manufacturing of a breadboard with new MLI installation method

- Mechanical testing (incl. depressurization test) of the selected concept

- Breadboard intended for critical function verification in a relevant environment

Application Domain

GEN-Generic Technologies

Technology Domain

21-Thermal

Competence Domain

2-Structures, Mechanisms, Materials, Thermal

Initial TRL

TRL 4

Target TRL

TRL 5

Achieved TRL

TRL 5

Public Document

Executive Summary

Final Presentation