Development and integration of embedded sensors for advanced manufacturing processes

Programme

GSTP

Programme Reference

GT1A-319MS

Prime Contractor

MAANA ELECTRIC SA

Subcontractors

LUXEMBOURG INSTITUTE OF SCIENCE AND TECHNOLOGY

Luxembourg

Start Date

End Date

Status

Contracted

Country

Luxembourg

Objectives

The objective of this activity is to develop the technologies to embed COTS sensors (e.g. strain, temperature) during manufacturing.

Description

Within the domain of smart manufacturing, the acquisition of data is of fundamental importance. There is clearly a need to extract as much information from the manufacturing process as possible (big data) through the use of sensor technology and in line process monitoring. There are a wide range of sensors which are commercially available which are used in a number of manufacturing sectors (automotive, aerospace, etc). Types of sensors include temperature, pressure, strain, and acoustics.

Where possible, the embedded sensor technology shall provide data during the manufacturing process, during transportation and storage on earth, during the launch phase, operational lifetime of the satellite/spacecraft, and during the final demise stage.

A key pillar common to all embedded sensor applications is the ability to transfer the data produced, thus this activity should also include the embedding of the data transfer technology. There are several possibilities to achieve this including embedded conductors or wireless devices.

In this activity the following tasks will be performed:

- To identify a number of products which will benefit from the introduction of embedded sensors, and the associated manufacturing processes.

- To perform a review of current sensor technology which will identify the type of sensor which is needed and to see if the sensor technology is currently commercially available.

- To develop the manufacturing process so that the sensors can be successfully embedded during manufacturing, and to ensure that the information generated by the sensor can be read with minimal interference to MAIT and systems architecture.

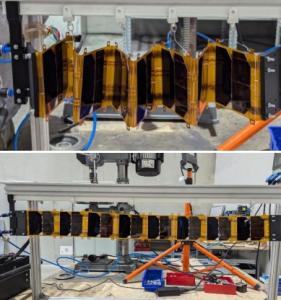

- To manufacture and test a prototype part.

Application Domain

GEN-Generic Technologies

Technology Domain

24-Materials and Manufacturing Processes

Competence Domain

2-Structures, Mechanisms, Materials, Thermal

Keywords

38-Advanced Manufacturing

Initial TRL

TRL 3

Target TRL

TRL 5

Achieved TRL

TRL 4

Public Document

Executive Summary

Final Presentation