Evaluation of LFoundry mixed-signal 150nm CMOS process (LF15A) for Space Applications

Programme

GSTP

Programme Reference

G617-202QT

Prime Contractor

SITAEL S.P.A.

Subcontractors

IMT srl

Italy

LFOUNDRY S.R.L.

Italy

REDCAT DEVICES SRL

Italy

THALES ALENIA SPACE ITALIA SPA

Italy

UNIV PADOVA

Italy

Start Date

End Date

Status

Closed

Country

Italy

Objectives

To technically evaluate and assess the basis of a potential mixed-signal ASIC European supply chain based on LFoundry 150nm mixed-signal technology.

Description

Requirements for standard CMOS technologies when intended for space application are very close to that of terrestrial high reliability ground applications, characterised by signal-to-noise, voltage and frequency performance parameters, depending on the ground domain itself. However, for space application, long term reliability and radiation resistance are mandatory and are currently not proven for aerospace, automotive or industrial components.

Nowadays, improvement of standard CMOS technologies radiation tolerance are mainly achieved by design and only in rare cases through process modifications. While for digital circuits effective radiation mitigation techniques have been demonstrated, for mixed-signal circuits, testing, debugging and redesign activities are a costly, lengthy and do not necessarily always result in the desired improved radiation tolerance.

This activity will therefore consist in the technical evaluation of LFoundry mixedsignal 150nm CMOS process (LF15A) to assess its suitability for space application especially in terms of reliability and radiation tolerance.

The activity will be organised in 5 tasks :

- Task 1: Documentation and definitions - Documentation of the process. Definition of representative test structures for evaluation of the LF15A in space applications based on the analysis of existing structures, suitable to assess the existing cell library/libraries and manufacturer validated IP modules and particular emphasis on their response to the space radiation environment, especially transients. Formulation of the Evaluation Test Plan (ETP) using ESCC 2269000 as a guideline and taking into account existing, pertinent reliability test data demonstrating compliance with reliability and environmental robustness requirements specified for space applications.Technical visit of the different actors of the potential supply chain (Design, CMOS processing, assembly, test, etc).

- Task 2: Reliability assessment - Intrinsic reliability assessment of the LF15A technology, based on the characterization of the available basic primitive and specific devices for space applications. Design and redesign of specific test-vehicles (if any), preparation of test set-up and execution of reliability characterization.

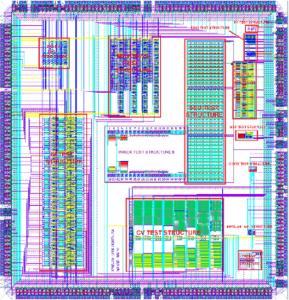

- Task 3: Test vehicle design and fabrication - Design and redesign of specific test-vehicles as agreed in Task 1 and preparation of the test-setups and automatic test programmes to be used for the ETP.

- Task 4: Fabrication and Evaluation testing and results - Fabrication and when required packaging of all test-vehicles for the execution of the ETP. After Test Readiness Review (TRR) performance of evaluation testing in line with the agreed ETP.;

- Task 5: Finalisation and future work - Analysis of all results including radiation, life test, step stress test etc., preparation of the process evaluation test reports. Update of electrical simulation models as required by ETP results and update of process user documentation as required for future space users. Preparation of preliminary Space LF15A Data Book including preliminary description of Space LF15A library/IP resources for designers. Recommendation for future work including the identification of future radiation hardening activities needed, (if any).;

Application Domain

Generic Technologies

Technology Domain

23 - Electrical, Electronic and Electro-mechanical (EEE) Components and Quality

Competence Domain

1-EEE Components, Photonics, MEMS

Initial TRL

TRL 2

Target TRL

TRL 4

Achieved TRL

TRL 4

Public Document

Executive Summary