Fibre-steering for lightweight cost-efficient space structures

Programme

GSTP

Programme Reference

GT17-486MS

Prime Contractor

ICOMAT limited

Subcontractors

MT AEROSPACE AG

Germany

Start Date

End Date

Status

Closed

Country

United Kingdom

Objectives

The objective of this activity is to further develop the rapid tow shearing (RTS) process on singly-curved surfaces in order to optimise its performance for larger scale applications. The objective of the Phase 2 is to complete the detail design, manufacture and static testing of a representative breadboard central tube specimen, to use the results to demonstrate the quality of 3D-RTS hardware and to assess the maturity of 3D-RTS technology for parts that are ready to be industrially scaled and proposed for flight hardware.

Description

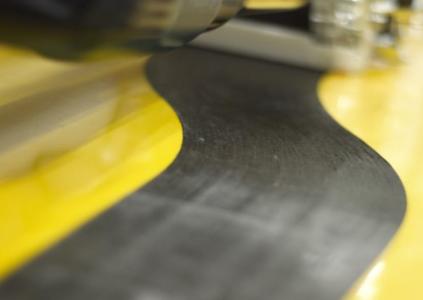

RTS is currently being used to provide fast carbon-fibre-reinforced polymers (CFRP) manufacturing of aerospace grade demonstrators that are higher quality and lower mass than conventional auto tape laying (ATL) or auto fibre placement (AFP) processes.

;

The previous GSTP activity, G617-241TAeq ? De-risk assessment: Fibre-steering for lightweight and cost-efficient space structures demonstrated high potential for capturing similar performance (similar buckling behaviour of compression tubes, but lower mass) for space related applications. A key requisite for using the RTS process for structural applications on launch vehicles and satellite central tubes is the ability to deposit directly on a singly-curved tool/mandrel. Rapid tow shearing on singly-curved surfaces has been demonstrated in lab-scale, but further development is needed to optimise the performance of the RTS process for larger scale applications.

;

The topic of permeability of composites shall also be addressed in the proposed activity. Permeability of composites that contain fuels (tanks and launcher structures) is a challenge and an area of active investigation in launch structures. The unique ability of RTS to steer without defects, gaps or overlaps could improve the permeability of such structures. Coupon-level tests shall be carried out under loading and various temperature conditions and shall generate data for comparison with AFP. If results are promising, future work could include pressure vessel tests.

The tasks foreseen in the frame of this activity are the following:

?Phase 1 (budget: 1,100; duration: 18 months)

oDevelop and build a bespoke RTS machine for defect-free robotic fibre placement of 2.5D space structures, focusing on direct-to-mould deposition of cylindrical structures. Key developments required are a modification of the compaction mechanism to account for the curvature of the mould and the ability to use narrower tapes (lt;100mm).

oManufacturing and testing at coupon level, to demonstrate the updated 2.5D-RTS hardware provides the same defect-free performance as the 2D system demonstrated during the de-risk.

oCreate an RTS tow-steered technology demonstrator for novel lightweight satellite central tubes. This includes demonstration of benefits from steering around interface holes and locations where high shear and pull-out loads will be input to the central tube by attached shear webs and propulsion systems.

oComplete manufacturing readiness review prior to launching complex demonstrator manufacture.

?Phase 2 (budget: 425 k?, duration: 15 months)

oGenerate a demonstrator breadboard detail design, manufacturing drawings and detailed test plan that will enable the manufacture and mechanical test of the demonstrator breadboard.

oGenerate predictions of the expected behaviour for critical areas and key overall performance criteria under selected load cases, and an instrumentation plan for all sensors and measurement systems.

oComplete manufacturing of the demonstrator breadboard, by depositing directly onto a cylindrical tool surface using the 3D-RTS system developed in Phase 1.

oPerform all necessary Non-Destructive Testing (NDT), metrology measurements, and quality control checks to verify the quality and completeness of the demonstrator.

oPerform mechanical testing on demonstrator breadboard using the test configuration and load cases defined and compare against predictions. Demonstrate any benefits of RTS in high load regions over conventional or 2D deposition methods.

oBased on the correlation achieved at different levels of the test pyramid, define further development paths needed to mature RTS technology for manufacture of the target space central tube applications as well as the potential of extending to primary launch vehicle structures, such as CFRP upper stages. Provide a design handbook for using 3D-RTS in space hardware design.

Application Domain

GEN-Generic Technologies

Technology Domain

24 - Materials and Manufacturing Processes

Competence Domain

2-Structures, Mechanisms, Materials, Thermal

Initial TRL

TRL 4

Target TRL

TRL 6

Achieved TRL

TRL 5

Public Document

Executive Summary