Improvement of microvibration prediction and verification methods

The objectives of this activity are to improve key points of microvibration prediction and verification methodology for spacecraft. The main aspects are the modelling of disturbances in structural analysis, the analysis methods in frequency and time domains and the verification methods.

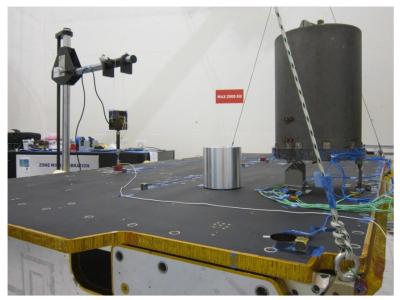

This activity is split in different parts focusing on various aspects of the overall methodology: 1) Models and structural analysis development, fidelity and coupling: Noise source models are the starting point of microvibration analysis. Some sources are well known and modelled (e.g. Reaction wheel) but others still require some development. In particular, cryo-cooler and stepper motors models are often key to microvibration performance but are generally based on black-box models coming from test characterization without a model representation of the physical phenomena. The source model fidelity shall also be improved (including potential non-linearities, actuators, sensors, controllers...) and verified against test characterization. The coupling of these models to the S/C model (usually FEM) is also a key aspect driving the way the source model will be developed. This coupling shall be improved and more standardized. 2) Prediction analysis methods: in the frequency domain (which remains the main domain of analysis), an improvement of summation rules of microvibration contributors associated to disturbances degrees of freedom, harmonics, and combination of simultaneous sources is necessary. The objective is a better estimation of the statistical confidence level of the microvibration performance metric using realistic ways of combining the above-mentioned contributors In the time domain, a more systematic method to derive state-space models (e.g. modal state-space for the S/C structure, linearised state-space models for some noise sources) and the way to couple them efficiently shall be put in place. Use of multi-body dynamic formulation for some mechanism shall also be explored to be able to model accurately the underlying physical phenomena (linked to point 1) 3) Microvibration testing techniques: Microvibration testing at payload or system level is usually limited due to external background noise, MGSE limitations, configuration setup. This usually prevents real end-to-end testing and is leading to simplified testing configuration (e.g. transfer function measurements, reduced number of measurements...). Improving the end-to-end verification of the microvibration performance based on these simplified testing combined with dedicated analyses is also considered necessary.