Material Characterization Service Efficiency Increasing

Programme

GSTP

Programme Reference

GT17-151MS

Prime Contractor

ENERGIE TECHNOLOGIE GMBH

Subcontractors

Start Date

End Date

Status

Closed

Country

Germany

Objectives

The objective of the activity is to optimise the turnaround times of the different test methods and campaigns for material characterisation by focusing on three activities:

- Shortening the warm-up time of the test apparatus after cryogenic testing

- Improving the tools and the components of the test machine in order to reduce set-up and disassembly time

- Addressing methods for process automatization with respect to 24h operation including safety aspects

Description

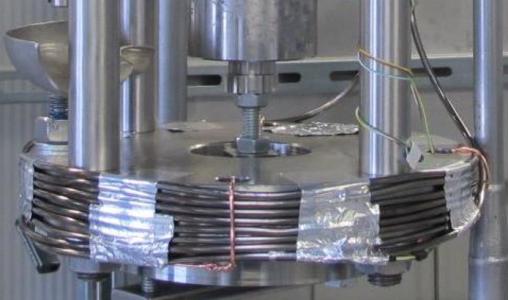

This activity aims at increasing the efficiency and decreasing the turnaround time of material testing capabilities in novel cryogenic fluids, notably liquid hydrogen (LH2).

Improvements in testing throughput could significantly improve the capacity of the test setup, allowing additional efficiency and availability for industry and for testing under ESA contracts and industry. This would reduce turnaround time and costs for testing. A first estimation indicates a reduction of the set-up times by 30% and the warm-up times by 50%. A significant increase of efficiency for long term tests by process automation is also targeted.

The activity will assess/validate three key efficiency improvements in the following corresponding tasks:

- Shortening of warm-up time. Warm-up time could be improved by the addition of specialised heaters and/or heat exchanger compatible with the hydrogen environment. This could increase throughput by significantly reducing the time between individual tests.

- Tool and component adaptation. Adaptations could improve handling efficiency for basic operations such as flushing, filling and emptying the cryostat. Adaptation would reduce the time needed for set-up and disassembly.

- Process automatization. These process implementations could significantly reduce the time and effort needed for long-term tests such as fatigue testing, where tests can last many hours/days and otherwise would need to be constantly monitored.

The targeted optimizations will help to reduce the duration of a test campaign, to reach results in due time and to keep deadlines within industrial development processes. The proposed improvement of the performance and efficiency is essential to reduce cost and adjust procedures to industrial standards.

Application Domain

Generic Technologies

Technology Domain

24 - Materials and Manufacturing Processes

Competence Domain

2-Structures, Mechanisms, Materials, Thermal

Initial TRL

TRL 3

Target TRL

TRL 4

Achieved TRL

TRL N/A

Public Document

Executive Summary