Process-Structure-Property Modelling of Powder-Bed Additive Manufacturing Parts for Space Applications

Programme

TDE

Programme Reference

T724-610MS

Prime Contractor

VTT TECHNICAL RESEARCH CENTRE OF FINLAND LTD

Subcontractors

Electro Optical System Finland Oy

Finland

Start Date

End Date

Status

Closed

Country

Finland

Objectives

To develop a modelling tool for the effect of additive manufacturing process parameters on the microstructure and properties of the printed material.

Description

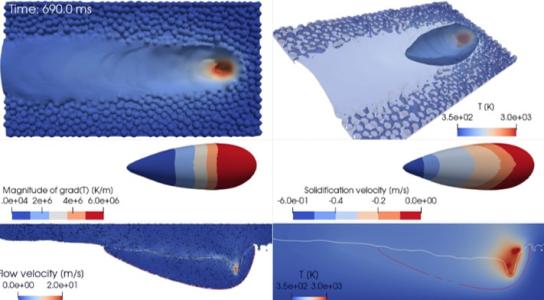

Powder-bed metal additive manufacturing processes allow to build three-dimensional parts by successive formation of pools of molten metal, which solidify on the previously built layers. Multiple parameters influence the generated microstructure, including the power input on the deposited metal, the powder particle size, the printing pattern and the layer thickness. Changes in one or several of those parameters affect the grain structure of the material and therefore the resulting mechanical properties of the printed part. Understanding of the relations between the applied process parameters, the generated microstructure and the resulting material properties appears therefore fundamental, not only to predict and optimize the properties of the printed parts, but also to induce gradient properties in a given part, by varying the process parameters during the build job. Process and material modelling tools are reaching the maturity where the interactions between process parameters and obtained microstructure can be predicted, for the complex additive manufacturing processes.

Therefore, it is needed to develop a reliable tool for modelling of the parameter-microstructure-property interactions and to validate this tool by experimental verification on printed specimens.

This activity encompasses the following tasks:

- A review of existing modelling tools ? and their limitations ? for prediction of the interaction between process parameters, developed microstructure and mechanical properties for powder-bed additive manufacturing parts

- Selection of a powder-bed additive manufacturing process and a metallic alloy for which the tool will be developed and validated. Identification of key process parameters influencing the microstructure of additive manufactured material

- Development of the modelling tool for by simulation of the additive manufacturing process on the selected material, varying the selected key process parameters

Application Domain

Generic Technologies

Technology Domain

24 - Materials and Manufacturing Processes

Competence Domain

2-Structures, Mechanisms, Materials, Thermal

Keywords

38-Advanced Manufacturing

Initial TRL

TRL 2

Target TRL

TRL 3

Achieved TRL

TRL 3

Public Document