Scalable Large Area SiPM

Objective(s)

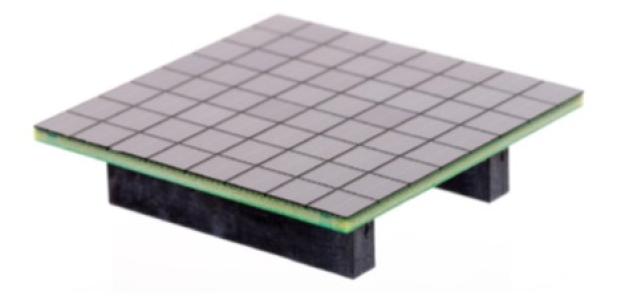

To develop, qualify and make production ready, a ball-grid array (BGA) SiPM detector based on TSV technology

Background and justification:

While Silicon Photomultipliers (SiPM) are recognized high-performance detectors, the manufacturing process results in significant dead space when they are used to form larger arrays, which is frequently necessary for both space and ground-based applications. By developing a new SiPM manufacturing process using established Through-Silicon-Via (TSV) technology, detector arrays with minimal dead space should be feasible, offering greatly improved performance and compact detector design.

Achievements and status:

The program saw the successful development of a large area TSV packaged SiPM which was subjected to a full characterisation, qualification and reliability assessment testing. Through this program SensL were able to develop a large area process technology required to package SiPM in a manner which allows them to be tiled with minimal dead space between sensors.

Benefits:

The results of this activity has successfully lead to the development of a new product, the MicroFJ-60035-TSV which SensL is now selling to commercial customers. The process technology is also under consideration for future high-energy astronomy missions.