Solar Cell Interconnector Design Optimization for Surviving Harsh Fatigue Environments

Programme

GSTP

Programme Reference

G611-031EP

Prime Contractor

Leonardo S.p.a.

Subcontractors

Start Date

End Date

Status

Closed

Country

Italy

Objectives

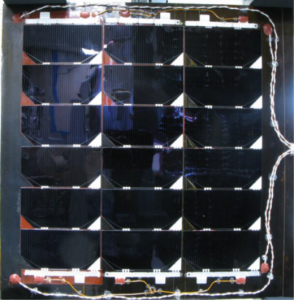

The objective of the activity the demonstration of a modified Photo-Voltaic- Assembly (PVA) technology based on:

- Verifications of the limits and margins of the proposed PVA technologies.

- Characterization of improved design by accelerated mechanical fatigue and thermal cycles tests.

Description

Recent extended LEO qualification programs revealed marginalities heritage interconnect design. In order to overcome this issue new designs have to be developed and verified. Although nominal loop design already demonstrated to be suitable for several mission environment, it is also evident that when operated outside the nominal design range could fail earlier than expected.

The activity will include analysis and experimental verification of the PVA and in particular of the solar cell interconnnector.

In order to verify the limits of the proposed PVA interconnect technology, the following tasks are proposed:

- Non-linear mechanical analysis.

- Flex test on several interconnects.

- Sensitivity analysis on the most important design parameters.

- Ad hoc characterization (thermal shock cycles) for demonstrating analysis results.

- Coupon test under thermal vacuum and thermal cycling environment up to 100,000 cycles in LEO temperature range.

Starting from the existing PVA design, strings on representative CFRP substrates shall be integrated and this hardware submitted to an environmental qualification campaign. The substrates dimensions will be such that strings can be laid down using nominal flight processes and sufficiently small to comply with available thermal shock chamber dimensions.

Inspection steps are foreseen every 20k cycles up to 100k cycles while continuity monitoring will be performed regularly on cells and bypass diodes.

This verification is aimed to:

- Confirm the suitability of PVA material selection and design.

- Quantitatively evaluate safety margins.

The following points have to be discussed and agreed prior to the start any qualification campaign:

- Substrate type and dimensions (preferred integration direction).

- Qualification temperature range.

Several substrates from various European manufacturers will be considered.

Application Domain

Earth Observation

Technology Domain

3 - Space Systems Electrical Power

Competence Domain

4-Electric Architecture, Power and Energy, EMC

Initial TRL

TRL 4

Target TRL

TRL 6

Achieved TRL

TRL 6

Public Document

Final Presentation

Executive Summary