Amorphous metals, a game changer to improve the efficiency of Space Cryocoolers

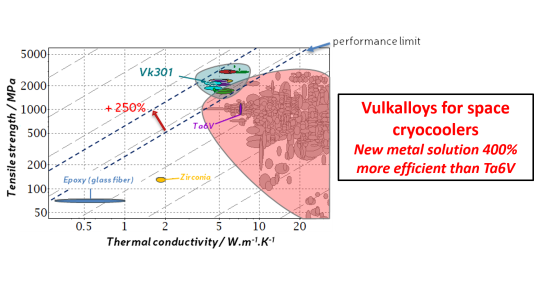

VULKAM, a French high-tech start-up specialized in amorphous metallic alloys (AMA), has developed a new range of materials with mechanical and thermal properties superior to those of Ti6Al4V. Vulkam is focusing on the industrialization and optimization of amorphous metals. Improving the efficiency of a cryogenic cooler is considered of great interest to space applications. Heat conduction losses in the cold finger of cryogenic coolers are one of the main causes of their lack of efficiency.

Vulkam, Lynred and Thales Cryogenics have proposed to ESA a 12-month OSiP evaluation study to assess the potential of these new materials in compact space cryocoolers.

Main Steps conducted during the study included:

- Theoretical study:

- Thermal analysis on current product

- Design and structural analysis of PoC demonstrator

- Approval approach baseline proposal

- Joining optimisation and qualification of the brazing method on simple parts

- Manufacturing of parts and assembling demonstrators (+ vérifications)

- Testing of final samples

Main Results and Achievements:

Thermal Performance of Vulkalloy Zr4 Validated

- Great expectations about thermal conductivity, losses, and general behaviour confirmed

- Consistency between thermal analysis and thermal loss evaluation on demonstrators: 1.8× reduction achieved

- More than 50% reduction of thermal parasitic losses

- Significant increase of ‘available cooling power’ for the same input power

Brazing Behaviour Insights

- First-time deep understanding of brazing between an amorphous metal and different crystalline alloys

- Preparation process and metallization improved for Vulkalloy® and each material

- Optimal configuration found for each base material

- Manufacturing of parts for demonstrators planned based on study results

Mechanical Performance Testing

- Not yet conclusive, but promising clues for further investigation

- One tested configuration appears promising (not far from passing)

- Joints are points with lowest MOS, not the AMA pipe

- Multiple isolated key findings may lead to compliancy if properly assembled

Conclusion & Perspectives

- Thermal analysis shows significant improvement in thermal efficiency and performance, demonstrated by boil-off measurements on samples

- Process optimizations, analysis, and qualifications necessary on final application