Development of new 3D printed magnetic materials for space applications

Magnetic materials, both with soft and hard magnetic behavior, are key components in many devices aboard any spacecraft, such as motors, mechanisms, actuators and sensors. The most common route for the manufacturing of magnets is the sintering process, which produces the highest magnetic performance possible but it is energy intensive and requires molds for each geometry. The alternative is the use of bonded magnets, which are composite materials composed of a polymeric matrix with a high content of magnetic filler. Being polymer-based, bonded magnets can benefit from all the manufacturing processes typical of polymers, such as extrusion, injection molding or filament based 3D printing. Therefore, the possibility of manufacturing magnetic components with an Additive Manufacturing process and with materials available in situ is a valuable perspective for the future of space agencies.

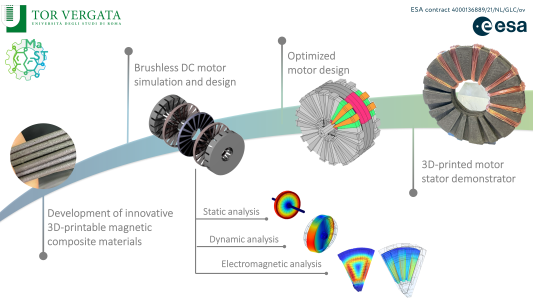

the aim of this project was to develop innovative composite and nanocomposite materials with soft magnetic fillers processable via Fused Filament Fabrication 3D printing to manufacture brushless motor components for space applications. With the developed materials, a brushless direct current motor was designed via Finite Element analysis to optimize the static, dynamic and electromagnetic performances arising from the mechanical and electromagnetic properties of the 3D printed soft magnets. Finally, a prototype of a motor stator with the optimized design and best performing material was 3D printed as a proof of concept of the application on the innovative composite for low power motors in space environment.