Development of a ruggedized frequency doubler

Objective(s):

Find an alternative supplier of non-linear crystals in a waveguide to strengthen the supply chain of the fibered frequency doublers and update the design. Formalize the manufacturing processes to ensure reproducible and more efficient production of frequency doublers. Carry various tests on the new crystals from the alternative supplier in exail package in comparison with reference crystals in exail package to validate the new crystal

Achievements and status:

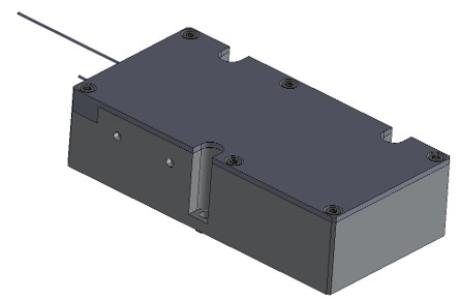

A specific opto-mechanical arrangement was designed to integrate crystals from both suppliers with minimal modifications. A dedicated manufacturing process was also developed. In total, 5 units were manufactured, 3 with the reference crystals and 2 with the new ones. Among them, 3 modules were tested in environments to demonstrate the reliability of our manufacturing process. The remaining 2 units undergone long-term endurance measurement. Exail has demonstrated its integration-capacity of such critical component which has been proven by quite successful tests in relevant environments. Still, some recommendations are proposed, considering the results obtained in environments, to further increase the robustness of this critical components and their implementation do not require modifications of our manufacturing process.