Evaluation and consolidation of Additive Manufacturing processes and materials for the manufacturing of RF hardware

Programme

GSTP

Programme Reference

G61A-035ET

Prime Contractor

THALES ALENIA SPACE ITALIA SPA

Subcontractors

POLITECNICO DI TORINO

Italy

Start Date

End Date

Status

Closed

Country

Italy

Objectives

Within this activity different AM processes, materials and post-processes for RF/microwave applications in space will be characterized. Multiple samples shall be designed and tested corresponding to several frequencies and applications.

Description

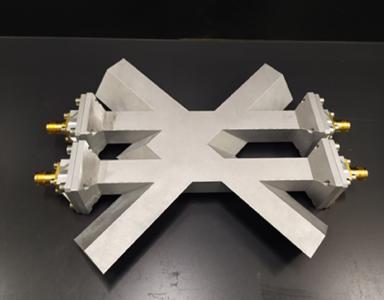

Additive Manufacturing (AM) is starting to be used for space applications. For future missions, many components could be manufactured using AM, also including primary structures or other mission-critical parts such as RF hardware. Final products such as feed components, beam forming networks, low and high power filters and RF harness can benefit from the advantages provided by AM. The overall maturity of this manufacturing technique has been increased in the last years offering a great variety of materials, processes and post-processes required to achieve the final part. The major efforts were so far focused on mechanical and thermal aspects. Very promising results have been already presented based on, for example, SLM in titanium or aluminium and stereolithography for ceramics.

Alongside the significant weight reduction, lead time and production cost, an important improvement for the RF performance (losses and PIM) can be potentially achieved through AM. The requirements imposed by the RF performance to AM need to be adequately considered for the selection of the best end-to-end AM-based process. In order to select the adequate end-to-end AM-based processes for RF hardware, the assessment and screening of materials, processes and post-processes need to be performed. This activity aims to characterise different AM processes, materials and post-processes already available in the market in order to pre-select the best candidates for RF hardware manufacturing. As a minimum, the following primary points shall be covered:

- Geometrical issues: accuracy, geometry complexity, maximum and minimum size, roughness, etc.

- Process robustness e.g. repeatability.

- Electrical issues: need of coating, electrical conductivity, SEY, outgassing, loss tangent, dielectric constant

- Post-processing methods

The pre-screening of manufacturing techniques must show the suitability of the end-to-end process based on previous in-house heritage considering the following secondary points:

- Physical properties: Density, porosity, thermal conductivity.

- Mechanical properties: static and dynamic

- Environmental issues: maximum/minimum temperature range, radiation, life time.

In order to perform this assessment and screening, a number of samples (RF samples and coupons) will be designed, manufactured and tested allowing the assessment of the feasibility for each set of [materials, AM process, post-process].

The test shall comprise RF measure and inspections (destructive and non-destructive) to verify the structural characteristics.

Application Domain

GEN-Generic Technologies

Technology Domain

24-Materials and Manufacturing Processes

Competence Domain

2-Structures, Mechanisms, Materials, Thermal

Keywords

38-Advanced Manufacturing

Initial TRL

TRL 2

Target TRL

TRL 4

Achieved TRL

TRL 4

Public Document

Final Presentation

Executive Summary