PCM-HSD Design, Assembly and Flight Testing

Develop mass-efficient heat accumulators using PCM (Phase Change Material) to avoid overheating of specific power demanding electronic boxes such as telemetry telecommand receivers and transmitters, data acquisition boxes ? for a flight opportunity on a payload launched by a sounding rocket. The activity will enable performing the complete cycle of design, manufacturing, integration and environmental testing for two different PCM heat accumulators according to specifications dedicated to a launch on a sounding rocket.

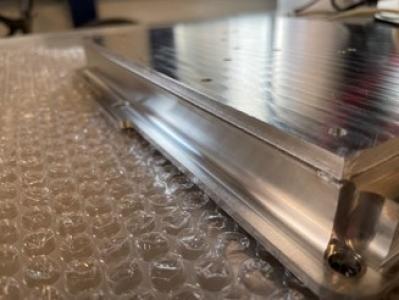

Based on the heat release of dedicated electronic boxes, a complete design, manufacturing and integration cycle will be performed for two different mass-efficient heat accumulators using phase change material avoiding overheat of specific electronic boxes on-board a launch vehicle.This includes also dedicated thermal, vibrational and structural analysis to withstand the complete flight mission with mounted electronic boxes. The PCM accumulators will be instrumented to retrieve and transmit data during flight such as temperatures, heat fluxes by an existing on-board data acquisition box and telemetry system.The different phases of the development will be compliant to related reviews, i.e. PDR, CDR, QR, AR and FRR. Therefore, the following elements will be elaborated and provided:1. Specification report 2. Design and Analysis Report: i.e. thermal and full structural analysis (mathematical models)3. Manufacturing Drawings4. Qualification Tests including thermal and vibrational testing5. All other types of reports such as test reports, description, ICD6. Qualification model (2) and final flight models (2).The performance of the heat accumulators will be validated both by ground experiments and post-flight analysis. This approach should bring the PCM accumulator to a flight-qualified product for short duration application such as sounding rockets, launch vehicles.