Planar and encapsulated SMD inductive electronic component qualification

Programme

GSTP

Programme Reference

G617-243QT

Prime Contractor

FLUX A/S

Subcontractors

Start Date

End Date

Status

Closed

Country

Denmark

Objectives

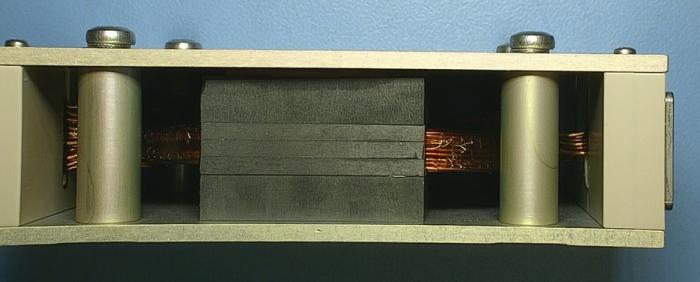

Further develop and qualify small planar components in Surface Mount Technology based on PCB and wound solutions and large planar components for High Power High Voltage application based on winding technology.

Description

It is proposed to develop and optimize encapsulation technology for the transformation of traditional Through Hole Mount electronic inductive components into Surface Mount Technology. This will involve the development and industrialization of encapsulation process and the development of mechanical elements for the integration of traditionally applied geometries of inductive components. The proposed activity is a continuation from a GSTP 4 activity (G604-11EP Study). The goal of that activity was to assess materials and technologies related to a series of planar inductive components. It was demonstrated that the materials, processes and mechanical designs were suitable for space applications. The possibilities of making surface mount components are today limited to designing with existing solutions picked from industry and making custom solutions by application of Injection Moulding. Injection moulding requires expensive tooling for each design and can hardly be considered an overall generic solution for manufacturing of custom components. Transforming traditional through-hole designs into surface-mount designs could potentially cutting production cost up to 90% on board level. By supplying parts in surface mount rather than through hole, the PCB mounting process changes from manual labour to fully automated process.

The opportunity in both planar inductive components and transformed traditional topologies into surface-mount technology requires reducing cost while preserving the possibility of custom designing complex components to suit the requirements of scientific equipment, as well as to boost the power levels particularly needed for large satellites, electrical propulsion and constellations. The possibilities of designing more powerful planar transformers using foil and wire technologies, as demonstrated under the GSTP 4 activity, support the need within electrical propulsion circuits. The activity will lead in a second (future) step to the completion of an ESCC qualification.

Deliverables:

PID and Reporting on the Encapsulation Process and test results, designs and product specifications including developed casings for manufacturing, components for verification testing and Qualification.

Application Domain

Generic Technologies

Technology Domain

23 - Electrical, Electronic and Electro-mechanical (EEE) Components and Quality

Competence Domain

1-EEE Components, Photonics, MEMS

Initial TRL

TRL 4

Target TRL

TRL 6

Public Document

Executive Summary

Final Presentation