Preliminary reliability assessment of a European 0.25um GaN HEMT process

Programme

GSTP

Programme Reference

G617-169QT

Prime Contractor

Leonardo S.p.a.

Subcontractors

IMT srl

Italy

Start Date

End Date

Status

Closed

Country

Italy

Objectives

GaN based MMICs are very attractive for realising high-power, high-efficiency integrated circuits for radar, communication and general purpose microwave space applications. The availability of European, space qualified, GaN MMIC foundry processes is needed to allow space industry to gain access to this disruptive technology. The objective of this activity is to perform a preliminary performance and reliability assessment of a general purpose European 0.25um gate GaN MMIC foundry process using a 100% European supply chain (i.e. SiC substrate, epitaxy and device processing) to allow full European non-dependence. This activity shall pull through the successful work from previous ESA GSTP and EU funded activities (e.g. in terms of GaN epitaxy (G517-050QC, G517-128QT) and SiC substrate development (FP7 EuSiC). The work program shall allow identification and correction of any process weaknesses, in terms of space applicability, prior to starting a formal space qualification/evaluation as part of a separate follow on activity.

Description

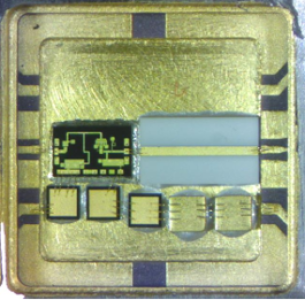

The activity aims to undertake a dedicated program of work to optimise the epitaxy, perform material characterisation, device processing trials, thermal modelling and prove the space suitability of the foundry process for manufacture of general purpose GaN based MMICs (e.g. HPAs, LNAs, switches) by extensive test and validation. The foundry supplier shall implement corrective process improvements, when/if required, to ensure compatibility with space operating requirements. The baseline activity can be divided into four primary tasks:

- Epitaxy optimisation. The objective is to identify the optimum choice of epitaxy, using a European supplier, and investigte processing techniques suitable for realising space compatible GaN based MMICs. Specifications shall be derived to achieve appropriate RF performance characteristics and to minimise the effects of trapping that are known to have an detrimental impact for some space applications (e.g. memory effects within multicarrier telecommunication links). A long term supply agreement shall be established for the use of European GaN epitaxy.

- Material characterisation: A material characterisation and feedback route shall be established through processing of multiple test structures in order to allow the epitaxy material characteristics to be determined and optimised.

- Device processing and measurement: Design, layout and processing of appropriate test structures shall be undertaken (e.g. PCM, TCV, DEC, RIC) and electrical characterisation performed. Appropriate tests shall be undertaken using these test structures to determine if there are any major reliability issues for operation in space. As part of this characterisation work, high temperature operating life (HTOL) testing shall be performed along with a preliminary assessment of radiation hardness. Multiple process iterations and feedback loops shall be undertaken to allow correlation between reliability and electrical performance versus the epitaxial material structure, device topology and processing methodology. A key aim of this tasks is to eliminate (or mitigate) failure mechanisms and performance shortfalls that may prevent the technology being used in space.

- Preliminary space evaluation: Once the basic process has been established and has shown good potential for operation in space, a preliminary space evaluation shall be made in which longer duration and more extensive reliability testing and space robustness testing is performed. This shall include long duration accelerated DC and RF life testing, high temperature reverse bias testing, storage tests, TID, proton and heavy ion radiation tests and a hydrogen poisoning assessment. If the outcome this task is successful the aim would be to initiate a follow on program, e.g. funded through ECI 5, to undertake a formal ESA space evaluation of the GaN MMIC process.

Application Domain

Generic Technologies

Technology Domain

23 - Electrical, Electronic and Electro-mechanical (EEE) Components and Quality

Competence Domain

1-EEE Components, Photonics, MEMS

Initial TRL

TRL 4

Target TRL

TRL 6

Achieved TRL

TRL 5

Public Document