Qualification of Additive Manufacturing for Antenna applications

Programme

GSTP

Programme Reference

GT1A-009MS

Prime Contractor

HPS GMBH

Subcontractors

Fraunhofer Gesellschaft

Germany

Start Date

End Date

Status

Closed

Country

Germany

Objectives

The aim of the activity is to mature the Additive Manufacturing (AM) process for antennas. In particular the objective of the activity is to identify the AM influencing factors during for the production of the selected part and to establish the respective Additive Manufacturing Procedure Specification.

Description

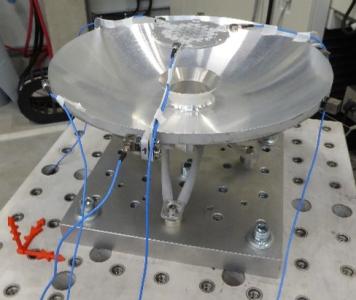

In the previous activity GSTP de-risk activity the use of Additive Manufacturing technology for the manufacturing of antennas for high temperature applications was proven feasible, allowing mass and cost reduction in the final part. Additionally the RF performance showed promising results, despite of the inherent the geometrical deviations and a rough surface finish.

;

Additive Manufacturing technologies are considered enabling by the European Space Industry and their introduction in space missions has been increasing rapidly over the last years. Nevertheless, the qualification of AM parts for ESA missions is still considered as a critical step.

;

As such, this activity intends to mature the use of AM on the road to future qualification of this process, in particular for RF related applications. The work shall follow the guidelines proposed by the Agency and agreed with the Contractor, which comprise four development phases: AM definition, AM pre-verification, AM verification and hardware production phases.

;

It is expected to that the Contractor addresses the referred development phases, focusing on a dedicated test campaign as means to issue the respective Additive Manufacturing Procedure Specification.

;

Therefore the main tasks for this activity include:

;

- Propose a maximum of two case studies, considering potential benefits of AM and space market needs for RF related applications.

- Identify the AM influencing factors for the production of the selected part, considering the lessons learned of the previous activity 3DPAN (AM definition phase).

- Establish working process window, post processing methods and Non-destructive inspection techniques for the selected part (AM pre-verification phase).

- Prepare an Additive Manufacturing Verification Test Plan for standard and / or part specific samples (AM pre-verification phase).

- Produce and test the samples (AM verification phase)

- Issue the respective Additive Manufacturing Procedure Specification, (AM verification phase).

- ;Manufacture a demonstrator according to the specification (Hardware production phase).

Application Domain

GEN-Generic Technologies

Technology Domain

24 - Materials and Manufacturing Processes

Competence Domain

2-Structures, Mechanisms, Materials, Thermal

Initial TRL

TRL 4

Target TRL

TRL 5

Achieved TRL

TRL 6

Public Document

Executive Summary

Final Presentation