Development of a digital twin for advanced manufacturing processes

Programme

GSTP

Programme Reference

GT1A-318MS

Prime Contractor

MT AEROSPACE AG

Subcontractors

Fraunhofer Gesellschaft

Germany

Start Date

End Date

Status

Closed

Country

Germany

Objectives

The objective of this activity is to develop a digital twin for a selected manufacturing process such as composite or additive manufacturing technologies.

Description

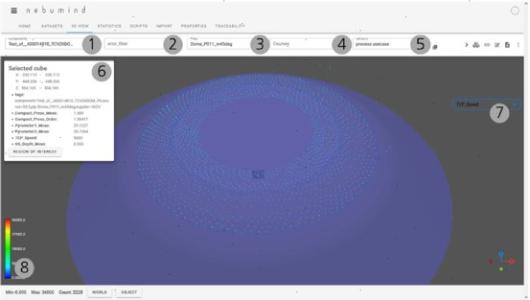

The concept of digital twins in industry relates to the development of data models for physical systems to accurately reproduce physical and performance characteristics of processes and products. It is often referred to as a virtual replica of the physical asset which can be used to monitor and evaluate its performance. In the scope of Industry 4.0, the digitalization of manufacturing processes bring significant potential in the improvement, namely in lowering manufacturing costs, improving performances, increasing reliability, and in reducing the time to market. In this context the use of digital twins is seen as an essential tool to predict capacity, rate, yield, performance, and feeding in data to failure analysis models. Three categories of digital twins can be considered:

- Supervisory: Passive process monitoring and identification of key thresholds.

- Interactive: Limited control capabilities of process parameters.

- Predictive: Full process simulation through model and data collection allowing real-time process control.

With this activity, the advantages of using a digital twin for a selected manufacturing process will be demonstrated including the following tasks:

- Select a case study for a relevant manufacturing process such as composite or additive technologies;

- Analyse the application of digital twins to the selected process, identify the variables to be measured, monitored, controlled;

- Develop and tailor the digital twin model;

- Implement and integrate the digital twin in the selected manufacturing process;

- Establish performance assessment and validation of the developed digital twin. This is possibly complemented by failure analysis models and physical performance analysis of manufactured parts;

- Assess the applicability of the developed digital twin tool to other MAIT processes in the space sector.

Application Domain

Generic Technologies

Technology Domain

24 - Materials and Manufacturing Processes

Competence Domain

2-Structures, Mechanisms, Materials, Thermal

Keywords

38-Advanced Manufacturing

Initial TRL

TRL 3

Target TRL

TRL 5

Public Document

Final Presentation