Highly Accelerated Life Test Pilot Supporting Agile Space Engineering

Programme

TDE

Programme Reference

T723-604QE

Prime Contractor

ALTER TECHNOLOGY TUV NORD S.A.

Subcontractors

FUNDACI?N ANDALUZA PARA EL DESARROL AEROESPACIAL

Spain

Start Date

End Date

Status

Closed

Country

Spain

Objectives

To reduce the development time with a proof of concept methodology and associated tool, targeting robustness of electronics boards tin the space environment

Description

Conventional bottom-up manufacturing and test methods are associated to a substantial portion of schedule and cost in the life cycle of a space product. Innovative methods that support agile development cycles, such as Highly Accelerated Life Testing (HALT) that started in non-space space domains are now becoming applicable for space product development and are already studied by many space companies, research institutions and space agencies. The goal is to draft a test flow that enables reliability testing at board level, removing the need to individually test and screen the components, materials and processes.

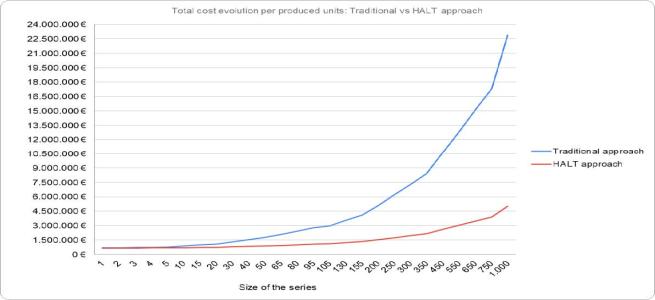

Proposal is to pilot these methods for a space product to reduce development time and cost of space hardware with a proof-of-concept unit. The following benefits are expected:

1. Increase the depth of knowledge of failure modes and their effect to the overall reliability of the product

2. Pilot the use of rapid prototyping enabling electronics boards usage in space

3. Define a technology development tool for HALT testing, creating a service center for European space ecosystem

4. Proof of concept methodology for an agile reliability engineering method

This activity encompasses the following tasks:

- Identify use cases, for example electronic boards developed or being developed with regular production (cubesat, telecom) of interest for space application

- Define tailored test method, plan, required tools and facilities for a HALT implementation (e.g. Thermal mechanical shocks, vacuum, vibration, radiation) In co-operation with Product Assurance experts, highlighting advantages with respect to current validation method

- Test a statistically significant amount of electronics boards until failure, using HALT Methods.

- Perform failure identification and calculate statistics (ie. Use data to develop failure profiles)

- Identify improvement actions to make the board robust to space environment.

- Perform a robustness hardening exercise on untested boards to make them withstand the HALT test

- Repeat the test with the hardened boards and observe whether the improvement actions were sufficient to make the board robust for space use

- Assess time reduction and propose recommendations for adoption of innovative methods that support agile development

Application Domain

GEN-Generic Technologies

Technology Domain

23-Electrical, Electronic and Electro-mechanical (EEE) Components and Quality

24-Materials and Manufacturing Processes

25-Quality, Dependability and Safety

Competence Domain

1-EEE Components, Photonics, MEMS

Keywords

40-Design to Produce

Initial TRL

TRL 2

Target TRL

TRL 3

Achieved TRL

TRL 6

Public Document

Executive Summary