Low stray light diffraction grating

Programme

TDE

Programme Reference

T116-601MM

Prime Contractor

Fraunhofer Gesellschaft

Subcontractors

STICHTING NEDERLANDSE WETENSCHAPPELIJK ONDERZOEK INSTITUTEN/ SRON

Netherlands

Start Date

End Date

Status

Closed

Country

Germany

Objectives

To reduce the amount of scattered stray light created by a diffraction grating

Description

With increasing demands on the sensitivity of remote sensing optical instruments, stray light has become an ever more critical issue. Diffraction gratings, which are key components of most spectral analysis optical instruments, contribute a particularly high amount of scattered stray light due to manufacturing imperfections. Diffraction gratings often represent the strongest contributor of scatter in a modern high performance instrument.

While over the past decade new design and manufacturing techniques have brought about an immense increase in design flexibility and grating performance as regards geometric realisation (e.g. freeform surfaces), spectral parameters (spectral distribution, resolution, dispersion) and diffraction efficiency, the generation of scattered stray light due to manufacturing imperfections of the grating structure still represents a contrasting issue.

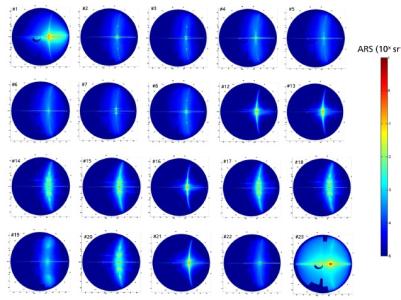

Regular variations of the grating grooves lead to the creation of ghost orders ("satellites"), while random variations create random scatter. For example, for ruled gratings the causes are typically mechanical variations during the ruling process. Techniques using etching processes typically feature stitching inaccuracies of the lithographic stepping process and small random variations of the grating grooves caused by fluctuations of the etch flow. Holographic techniques typically feature groove variations caused by imperfections of the illumination optics and possibly illumination laser speckle.

The proposed activity shall investigate for at least one modern grating technology the possibilities to improve design and manufacture with the goal of minimising stray light caused by grating imperfections.

The activity encompasses the following tasks:

- Investigation of the causes for scatter for the given design and manufacturing technology

- Proposition and elaboration of possible ways for improvement

- Implementation of at least the most promising option

- Verification by test

Application Domain

EO-Earth Observation

Technology Domain

16-Optics

Competence Domain

5-Radiofrequency & Optical Systems and Products

Keywords

2-Optical Payloads

Initial TRL

TRL 1

Target TRL

TRL 4

Achieved TRL

TRL 4

Public Document

Final Presentation