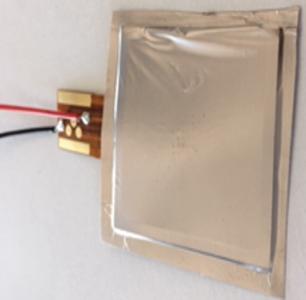

Variable Emissivity Radiator Breadboard

The objective of this activity is to develop a radiator breadboard equipped with variable emissivity tiles. The thermochromic and electrochromic technologies will be investigated, traded-off, and a down selection made. The most promising technology shall be integrated on a radiator breadboard, and tested in a vacuum chamber. The stability of the coated tiles and of the breadboard under representative Utra Violet and radiation for GEO missions shall be evaluated.

All telecommunications satellite radiators are typically covered with a low solar absorptance and a high infrared emittance coating. Because of the high emittance value, the satellite requires more power/battery for heating during eclipse. A tuneable infrared emittance coating can decrease it during an eclipse and can contribute indirectly to a reduction of the battery mass. A low absorptance coating minimises the solar heat load on the radiator and consequently its size and mass. As the actual radiator dimensions cannot be further increased, it is mandatory to manufacture coatings with a solar absorptance as small as possible tentatively <0.20 at End-of-Life (15 years for GEO). The activity consists of the following tasks : 1) The study will start with a survey of the State-of-the-Art on thermochromic and electrochromic materials. The best thermochromic (TCH) and electrochromic (ECH) technologies shall be selected for manufacturing. 2) TCH and ECH samples shall be manufactured and submitted to particles and UV radiation tests. Their physical properties (electrical, thermal, ESD) shall be measured and compared to each other before and after the tests. The test results as well as the system aspects of using such technology shall be also be part of the trade-off. One technology shall be selected for the breadboarding of a satellite (reduced) radiator. 3) A breadboard radiator, equipped with TCH or ECH tiles, shall be designed and manufactured. 4) The breadboard radiator shall be tested in near real flight conditions. In necessary, the breadboard will be submitted to particles and UV radiation tests. 5) The thermal performance and adequacy of radiator breadboard shall be evaluated and its performance compared to the current (fixed emissivity) radiator technology. A Roadmap for the qualification of the selected technology (ECH or TCH) shall be prepared.