Magnetically Shaped Spike Arrays for Field Emission Devices

Liquid metal ion thrusters (LMITs) are a type of electric propulsion system used for spacecraft. They work by ionizing and accelerating metal ions to generate thrust. The metal is typically either gallium or indium, which is heated into a liquid state and fed to the emitter. When a strong electric field is applied between the emitter and an extractor electrode, it pulls positively charged ions from the liquid metal surface at the tip of the needles. These ions are then accelerated by the electric field to extremely high velocities. The accelerated ion beam generates thrust according to Newton's third law of motion (Figure 2-1). LMITs produce very low thrust levels ranging from micro- to milli-newtons, but have exceptionally high specific impulses of 3,000 to 8,000 seconds. This makes them ideal for long duration station-keeping and attitude control maneuvers. The porous tungsten emitter is a critical component that largely determines the thruster performance and lifetime. However, manufacturing new emitters is challenging and expensive and this restricts the ability to iteratively test and optimize different emitter designs. Further research into optimized emitter fabrication methods could help accelerate prototyping and testing of new emitter designs, and reduce the overall expenses.

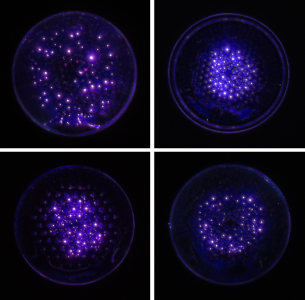

Here we propose a novel method of producing dense arrays of needle-like structures using magnetically shaped metal powder. Upon the application of a magnetic field, ferromagnetic powders are subjected to instabilities which give rise to the formation of typical arrays of spikes. The project objectives were to manufacture a variety of emitters using the proposed novel method and to test them in a working ion thruster prototype, with the main aim to assess their performance and durability.